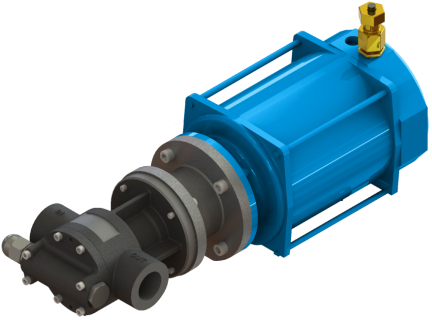

TP Series - Rotary Vane Transfer Pumps

Pollard Pumps’ new TP Series Rotary Vane Pumps are designed for the loading and unloading of tanks and tankers.

Flow range from 6m3/h to 60m3/h, these sliding vane pumps have been have been designed to facilitate transfers of hydrocarbons such as biofuels,

diesels, gasoline, lubricants and many others.

Simple. Robust. Efficient.

TP Series Transfer Pumps

TP Series Transfer Pumps

-

Flow up to 60 m3/h

-

Differential pressure up to 8 bar

-

Constant flow, self-priming, hose drain

-

Lower weight, higher flow rate

-

Self-lubricating with internal by pass

-

Robust construction allowing work in severe conditions

-

Designed following European Standard NF EN 809+A1

-

ATEX certification

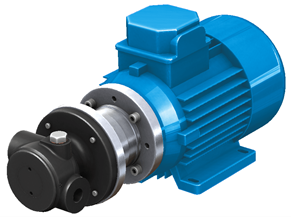

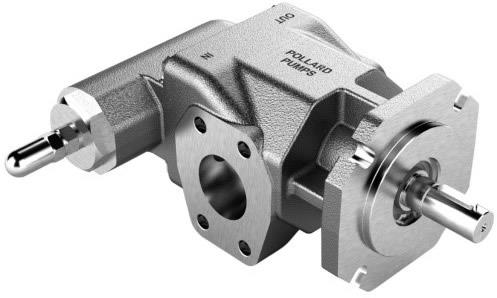

Motor Pump (MP) Series

The Pollard Pumps standard range of robust industrial pumps and motor pumps covers a range of capacities between

0.5cm³ and 665cm³ per rotation for pressures of up to 10 bar.

All models are equipped with Pollard’s CMtec technology which guarantees good volumetric efficiency, good suction capacity and the

ability to pump viscous fluids.

MP01 - MP02 - MP04 - MP06 - MP08

MP 1cm³ - 8cm³/Rotation

-

Designed to pump lubricating fluids (oil, diesel oil, etc.)

-

Flow rate is from 1 to 24 L/min for a working pressure up to 10 bar

-

The PR type pumps are equipped with the Reverse Plus system which allows rotation in both directions while maintaining the same flow direction of the fluid.

-

The MP type pumps exist in versions:

- Non reversible: MPX01 - MPX02 - MPX04 - MPX06 - MPX08

- Reverse Plus: MP01 - MP02 - MP04 - MP06 - MP08

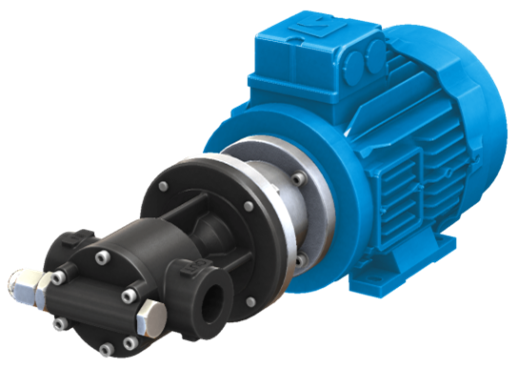

MP10 - MP16 - MP20 - MP25

MP 10cm³ - 25cm³/Rotation

-

Designed to pump lubricating fluids (oil, diesel oil, etc.)

-

Flow rate is from 1 to 37 L/min for pumps and from 7 to 37 L/min for motor-pumps; maximum working pressure up to 10 bar

-

The PR type pumps are equipped with the Reverse Plus system which allows rotation in both directions while maintaining the same flow direction of the fluid

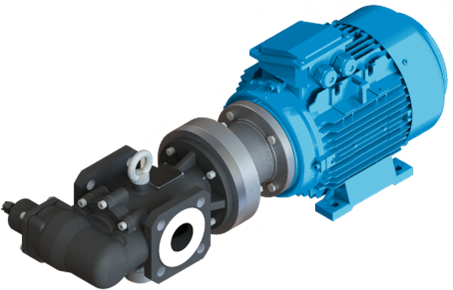

MP30 - MP40 - MP60 - MP67

MP 30cm³ - 67cm³/Rotation

-

Designed to pump lubricating fluids (oil, diesel oil, etc.)

-

Flow rate is from 1 to 90 L/min for pumps and from 20 to 90 L/min for motor-pumps; maximum working pressure up to 10 bar

-

The PR type pumps are equipped with the Reverse Plus system which allows rotation in both directions while maintaining the same flow direction of the fluid

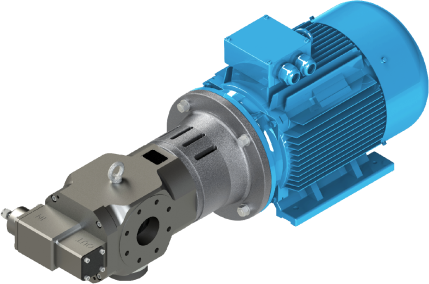

MP 70-225

MP 70cm³ - 225 cm³/Rotation

-

Designed to pump lubricating fluids (oil, diesel oil, etc.)

-

Flow rate is from 100 to 330 L/min for a working pressure up to 10 bar

MP 165-665

MP 165cm³ - 665 cm³/Rotation

-

Designed to pump lubricating fluids (oil, diesel oil, etc.)

-

Flow rate is from 250 to 1000 L/min, for a working pressure up to 10 bar

Micro Motor Pumps (MMP)

The different types of Pollard Micro Motor Pumps are designed to pump lubricating fluids (oil, diesel oil, etc.).

Pollard Pumps’ CMtec technology guarantees good volumetric efficiency, good suction capacity and the ability to pump viscous fluids.

MMP TYPE II 40 - 100 W

Micro Motor Pumps (MMP)

-

Suitable for pumping lubricating fluids (oil, diesel oil, etc.) for machinery

-

Low flow rates ranging from 70 to 200 L/hour for a working pressure up to 5 bar

MPEX 1cm³ - 60cm³ Rotation

Very specialised light petroleum liquids application.

MPEX 1-60 LV

MPEX 1cm³ - 60cm³/Rotation - ATEX

-

For optimum use of Pollard technology in an Explosive Atmosphere, our range is compliant with ATEX directive 2014/34/EU, and our quality

system meets standard EN 80079-34

-

ATEX certified with LCIE for flow rates from 1 to 60 L/min (at 1500 rpm)

PK PS - Interchangeability Vane Pumps

For lubrication and fluid transfer, a range of pumps adapted to customer’s system without additional cost.

PK PS - INTERCHANGEABILITY VANE PUMPS

PK PS - Interchangeability Vane Pumps for Lubrication & Fluid Transfer

-

Range starts from 2 cc/rev pumps to 80 cc/rev pumps and pressure up to 15 bar (g)

-

Economical solution designed to replace gear pumps by offering better performance, especially when pumping viscous fluids

-

The PK PS range was designed to offer the same interface dimensions as the gear series of competitors

-

This characteristic allows an easy pump interchange without any modification, for OEM or aftermarket use, as well as fast and easy maintenance

-

Numerous options to adapt in accordance with customer requirements